The SUBLIME project started its activities in May 2020 with the aim of developing new sulfide-electrolyte-based solid-state battery cells with high capacity and high voltage stability. Notwithstanding the increased difficulty of operating remotely due to lockdowns and limited travel possibilities from the start, SUBLIME has been making steady progress. Recently, we reached an important milestone by producing the first in-project generation of solid-state electrolytes that have attained and, in some cases, surpassed the targeted ionic conductivity values. Thus, low cell resistances will be achievable, enabling higher energy and faster charging of the developed batteries.

For solid electrolytes, one of the main challenges is to develop a material that has all the properties of liquid electrolytes (high conductivity, good wettability, ability to fill porous media, high electrochemical stability, etc.). Solid electrolytes, depending on the material, excel at some of these properties, but lack others. Sulfide electrolytes, for instance, have high ionic conductivities, however they lack electrochemical stability and, similar to all solids, good contact between electrolyte and electrodes is difficult to achieve. Although the malleable nature of sulfides is a mitigating factor, high pressures are required to obtain good performance (~50-150 MPa). In SUBLIME, partners are focusing also on ensuring strong mechanical properties to increase stability.

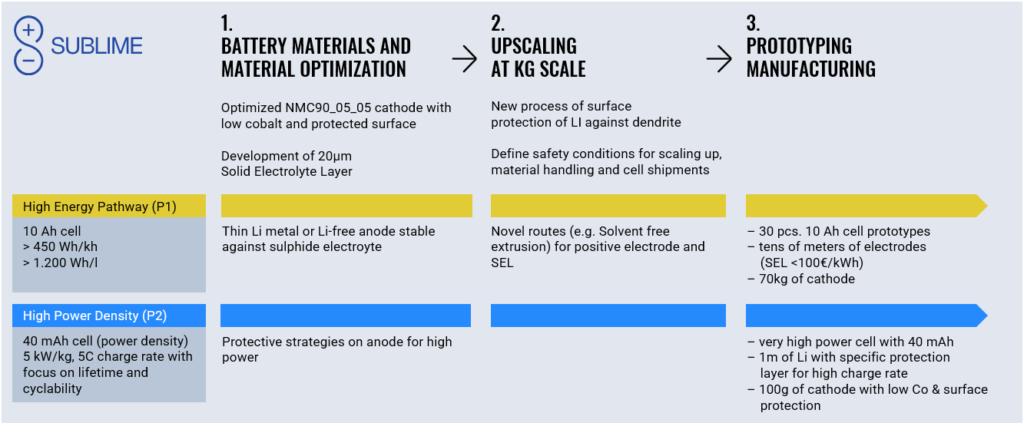

SUBLIME pursues two pathways towards lithium solid-state cells: a high-energy pathway and a high-power density pathway. The high energy pathway targets cells with high volumetric and gravimetric energy densities (1200Wh/l and 450Wh/kg, respectively), whereas the high-power pathway targets cells with high power density, enabling fast charging (5C) while maintaining good cyclability and lifetime. Both pathways build on a common materials base: SUBLIME uses Li metal as anode (LiM) and an NMC chemistry with low cobalt content and a protected surface as cathode.

Based on the developed electrolytes, the first lab-scale cells have been built and are delivering results, with further optimization in terms of capacity progressing in the high energy pathway. Research is now ongoing to manufacture thin layers (~30µm) of the electrolyte. Different processing methods and parameters (solvents, binders, additives) are being evaluated for optimization of the electrolyte. In parallel, electrode formulations are adapted to match the requirements of the sulfide electrolyte, ensuring stable interfaces with low resistances.

The challenges of developing solid-state batteries, however, extend well beyond the materials development and upscaling, even though these are already challenging tasks. They encompass the supply chain for materials and components; the safe handling and production processes for the novel materials (sulfide materials release hydrogen sulfide upon exposure to moisture); and the testing protocols for the resulting cells, as well as their ultimate recycling, to name just some.

Obtaining the needed materials and components from European suppliers has proven challenging in some cases. For instance, the procurement of lithium-coated current collector foil has highlighted a limited numbers of suppliers (particularly in Europe) and a high cost. Nevertheless, following supplier research, materials for lab cell manufacturing have been procured and the procurement path towards large cells has been defined.

To enable large-scale manufacturing of solid-state batteries in the future, the production processes and handling of materials need to be considered, as these may differ from those for previous generations of lithium-ion batteries. SUBLIME has formulated instructions on safe handling and processing sulfide-based electrolyte and solid-state cells.

Since SUBLIME aims to develop the complete value chain, the project work also covers the development of requirements and testing protocols for these new sulfide-electrolyte-based solid-state battery cells.